+86-13606279128

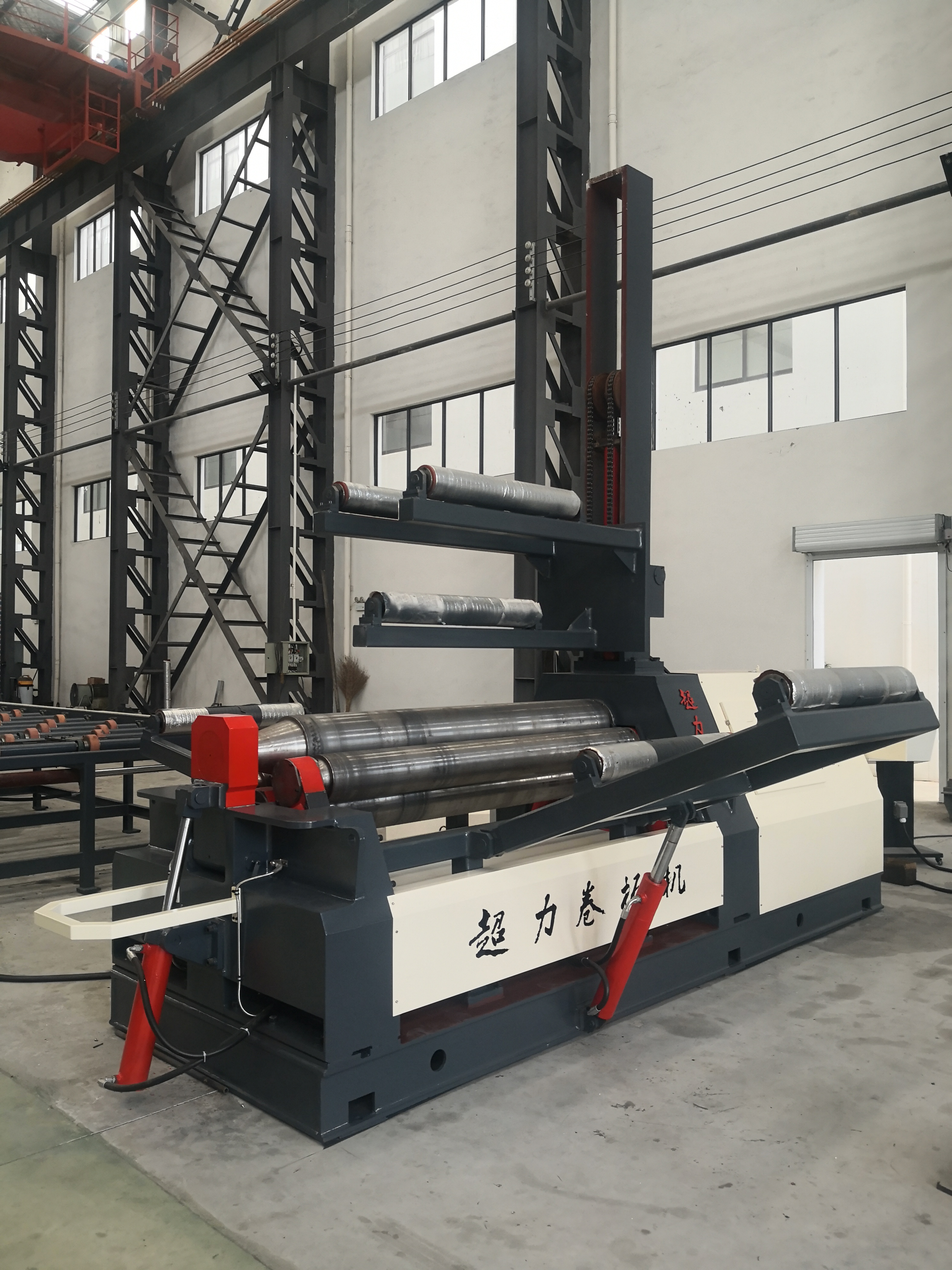

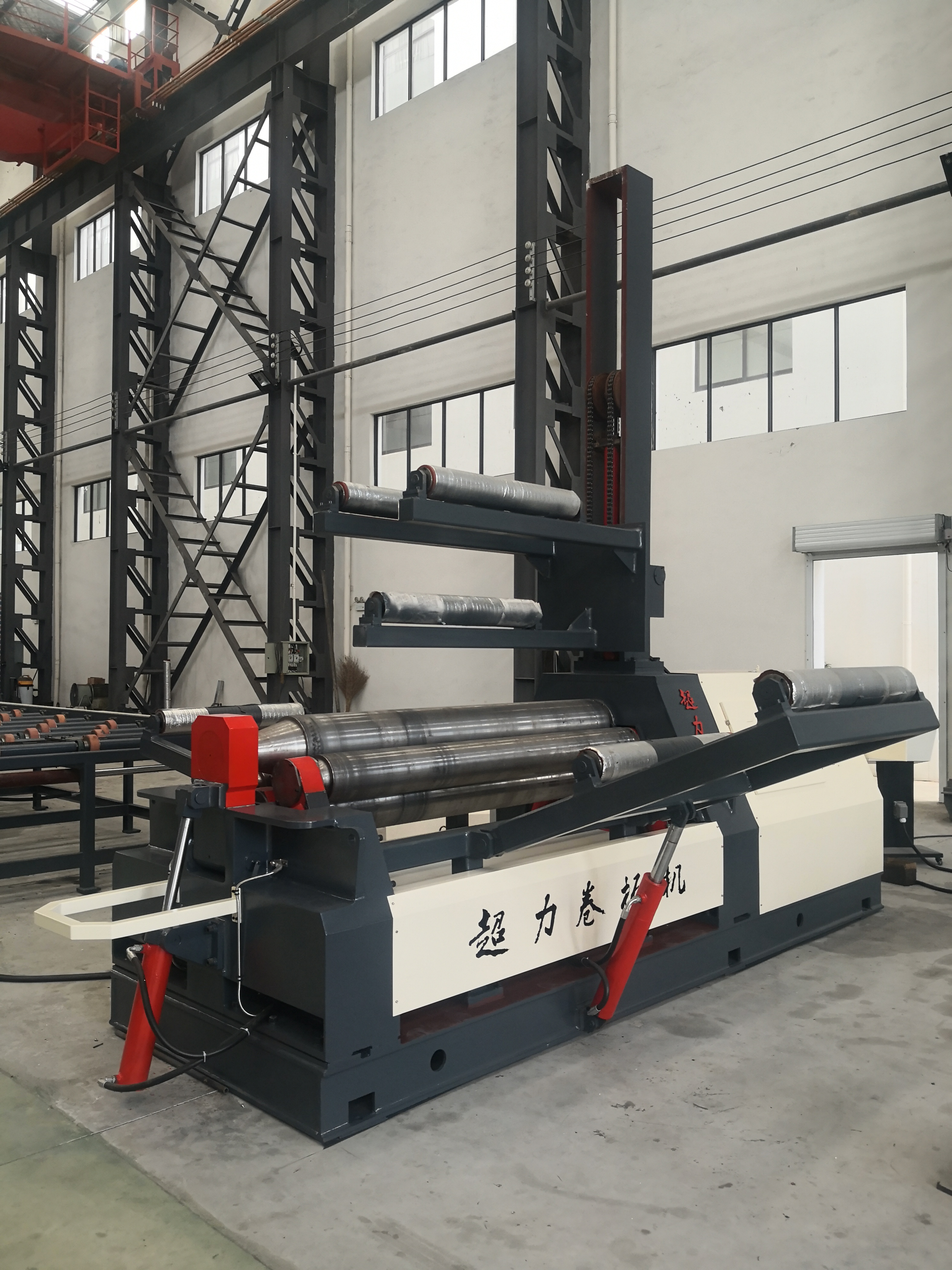

Automatic Hydraulic 4-roll Plate Rolling Machine can pre-bend the ends of plate and then roll it to specified shape with one time loading without reversing it.

| Availability: | |

|---|---|

| Quantity: | |

This machine can pre-bend the ends of plate and then roll it to specified shape with one time loading without reversing it. The working rolls on this machine are driving rolls and the lower rolls and two side rolls are hydraulically driven to move vertically. This machine is applicable to bending steel plate and can roll plate to cylindrical, arc or conical workpiece. It can also pre-bend ends of plate and center the plate, so rolling accuracy is high with small residual flat edge and high working efficiency. The steel plate can also be roughly flattened on this machine.

Chaoli four-roller coiler side roll lift adopts the patented technology of inverted hydraulic push side roll oil cylinder (patent number 201420466512.2), which brings the following technical advantages:Combining the oil cylinder and slider, the overall casting one-piece side roller sliding oil cylinder, which significantly increases the contact area between the slider and the slide rail and improves the stability of the side roller sliding;Combining the cylinder and slider into one piece shortens the length of the slide rail, reduces the overall equipment height and center of gravity, and reduces infrastructure construction costs;Inverted installation structure protects the seal ring, improves the service life of the cylinder and reduces the equipment breakdown maintenance rate.

Optional accessories:

The internal lifting material holder consists of fixed slide rail support, mobile lifting pick arm, hydraulic cylinder, transmission mechanism and hydraulic valve set and electrical control system. The stand can be lifted from up and down according to the size of the barrel, and support the barrel during the rolling stage to prevent the loss of roundness and overlapping feeding caused by the self-weight of the barrel. The height is measured by the travel encoder and the lifting height and movement are automatically controlled by PLC. Hydraulic cylinder driven load-bearing structure is adopted. The surface of the roller is quenched at medium frequency, with hardness of HRC52-58, and the roller surface is round-ground and chrome-plated.

Lateral support system,two-side hydraulic support or outer bracket: used to hold both sides of the large diameter barrel to prevent the steel plate from collapsing during the coiling process due to self-weight down causing poor coiling accuracy. Both sides of the hydraulic support respectively have multiple rows of rollers, in order to better support the barrel. The hydraulic support can be used as a roller path when it is released.

The roll cone device of four-roller plate rolling machine adopts our patented technology (Patent No.: ZL2009 2 0236158.3)

| Model | Max thickness | Max width | Upper roller diameterHydraulic electrical motor (Kw) | Bottom roller diameterHydraulic electrical motor (Kw) | Lateral roller diameter(mm) | Hydraulic electrical motor (Kw) | Min rolling diameter under full loading(mm) |

| W12-4x1500 | 4(3) | 1500 | 150 | 130 | 120 | 4 | 250 |

| W12-5x1500 | 5(4) | 1500 | 160 | 160 | 150 | 4 | 260 |

| W12-6x1500 | 6(5) | 1500 | 186 | 180 | 150 | 5.5 | 285 |

| W12-8x1500 | 8(6) | 1500 | 210 | 180 | 150 | 5.5 | 320 |

| W12-6x2000 | 6(5) | 2000 | 210 | 180 | 150 | 5.5 | 340 |

| W12-8x2000 | 8(6) | 2000 | 230 | 210 | 170 | 7.5 | 380 |

| W12-6x2500 | 6(5) | 2500 | 240 | 220 | 170 | 7.5 | 400 |

| W12-10x2000 | 10(8) | 2000 | 250 | 230 | 170 | 7.5 | 430 |

| W12-8x2500 | 8(3) | 2500 | 250 | 230 | 170 | 7.5 | 440 |

| W12-12x2000 | 12(10) | 2000 | 270 | 250 | 200 | 11 | 480 |

| W12-10x2500 | 10(8) | 2500 | 280 | 250 | 200 | 11 | 490 |

| W12-16x2000 | 16(12) | 2000 | 330 | 300 | 240 | 15 | 560 |

| W12-12x2500 | 12(10) | 2500 | 320 | 300 | 240 | 15 | 550 |

| W12-20x2000 | 20(16) | 2000 | 350 | 330 | 250 | 18.5 | 600 |

| W12-16x2500 | 16(12) | 2500 | 360 | 340 | 250 | 18.5 | 600 |

| W12-20x2500 | 20(16) | 2500 | 380 | 340 | 280 | 22 | 650 |

| W12-25x2000 | 25(20) | 2000 | 380 | 340 | 280 | 22 | 650 |

| W12-25x2500 | 25(20) | 2500 | 420 | 380 | 320 | 30 | 750 |

| W12-20x3000 | 20(16) | 3000 | 420 | 380 | 320 | 30 | 750 |

| W12-30x2500 | 30(25) | 2500 | 480 | 460 | 340 | 37 | 850 |

| W12-25x3000 | 25(20) | 3000 | 480 | 460 | 340 | 37 | 850 |

| W12-40x2500 | 40(32) | 2500 | 520 | 500 | 400 | 45 | 1000 |

| W12-40x3000 | 40(32) | 3000 | 560 | 540 | 420 | 45 | 1200 |

| W12-45x3000 | 45(35) | 3000 | 600 | 560 | 460 | 55 | 1500 |

| W12-50x3000 | 50(40) | 3000 | 620 | 600 | 470 | 55 | 1700 |

| W12-60x3200 | 60(50) | 3200 | 650 | 620 | 500 | 75 | 1800 |

| W12-70x3200 | 70(55) | 3200 | 700 | 650 | 560 | 90 | 2000 |

| W12-80x3200 | 80(65) | 3200 | 800 | 750 | 640 | 90 | 2000 |

| W12-100x3200 | 100(80) | 3200 | 860 | 800 | 700 | 110 | 2000 |

| W12-120x3200 | 120(100) | 3200 | 930 | 900 | 750 | 130 | 2500 |

| W12-150x3500 | 150(120) | 3200 | 1000 | 950 | 800 | 150 | 3000 |

|  |

|  |

|  |

This machine can pre-bend the ends of plate and then roll it to specified shape with one time loading without reversing it. The working rolls on this machine are driving rolls and the lower rolls and two side rolls are hydraulically driven to move vertically. This machine is applicable to bending steel plate and can roll plate to cylindrical, arc or conical workpiece. It can also pre-bend ends of plate and center the plate, so rolling accuracy is high with small residual flat edge and high working efficiency. The steel plate can also be roughly flattened on this machine.

Chaoli four-roller coiler side roll lift adopts the patented technology of inverted hydraulic push side roll oil cylinder (patent number 201420466512.2), which brings the following technical advantages:Combining the oil cylinder and slider, the overall casting one-piece side roller sliding oil cylinder, which significantly increases the contact area between the slider and the slide rail and improves the stability of the side roller sliding;Combining the cylinder and slider into one piece shortens the length of the slide rail, reduces the overall equipment height and center of gravity, and reduces infrastructure construction costs;Inverted installation structure protects the seal ring, improves the service life of the cylinder and reduces the equipment breakdown maintenance rate.

Optional accessories:

The internal lifting material holder consists of fixed slide rail support, mobile lifting pick arm, hydraulic cylinder, transmission mechanism and hydraulic valve set and electrical control system. The stand can be lifted from up and down according to the size of the barrel, and support the barrel during the rolling stage to prevent the loss of roundness and overlapping feeding caused by the self-weight of the barrel. The height is measured by the travel encoder and the lifting height and movement are automatically controlled by PLC. Hydraulic cylinder driven load-bearing structure is adopted. The surface of the roller is quenched at medium frequency, with hardness of HRC52-58, and the roller surface is round-ground and chrome-plated.

Lateral support system,two-side hydraulic support or outer bracket: used to hold both sides of the large diameter barrel to prevent the steel plate from collapsing during the coiling process due to self-weight down causing poor coiling accuracy. Both sides of the hydraulic support respectively have multiple rows of rollers, in order to better support the barrel. The hydraulic support can be used as a roller path when it is released.

The roll cone device of four-roller plate rolling machine adopts our patented technology (Patent No.: ZL2009 2 0236158.3)

| Model | Max thickness | Max width | Upper roller diameterHydraulic electrical motor (Kw) | Bottom roller diameterHydraulic electrical motor (Kw) | Lateral roller diameter(mm) | Hydraulic electrical motor (Kw) | Min rolling diameter under full loading(mm) |

| W12-4x1500 | 4(3) | 1500 | 150 | 130 | 120 | 4 | 250 |

| W12-5x1500 | 5(4) | 1500 | 160 | 160 | 150 | 4 | 260 |

| W12-6x1500 | 6(5) | 1500 | 186 | 180 | 150 | 5.5 | 285 |

| W12-8x1500 | 8(6) | 1500 | 210 | 180 | 150 | 5.5 | 320 |

| W12-6x2000 | 6(5) | 2000 | 210 | 180 | 150 | 5.5 | 340 |

| W12-8x2000 | 8(6) | 2000 | 230 | 210 | 170 | 7.5 | 380 |

| W12-6x2500 | 6(5) | 2500 | 240 | 220 | 170 | 7.5 | 400 |

| W12-10x2000 | 10(8) | 2000 | 250 | 230 | 170 | 7.5 | 430 |

| W12-8x2500 | 8(3) | 2500 | 250 | 230 | 170 | 7.5 | 440 |

| W12-12x2000 | 12(10) | 2000 | 270 | 250 | 200 | 11 | 480 |

| W12-10x2500 | 10(8) | 2500 | 280 | 250 | 200 | 11 | 490 |

| W12-16x2000 | 16(12) | 2000 | 330 | 300 | 240 | 15 | 560 |

| W12-12x2500 | 12(10) | 2500 | 320 | 300 | 240 | 15 | 550 |

| W12-20x2000 | 20(16) | 2000 | 350 | 330 | 250 | 18.5 | 600 |

| W12-16x2500 | 16(12) | 2500 | 360 | 340 | 250 | 18.5 | 600 |

| W12-20x2500 | 20(16) | 2500 | 380 | 340 | 280 | 22 | 650 |

| W12-25x2000 | 25(20) | 2000 | 380 | 340 | 280 | 22 | 650 |

| W12-25x2500 | 25(20) | 2500 | 420 | 380 | 320 | 30 | 750 |

| W12-20x3000 | 20(16) | 3000 | 420 | 380 | 320 | 30 | 750 |

| W12-30x2500 | 30(25) | 2500 | 480 | 460 | 340 | 37 | 850 |

| W12-25x3000 | 25(20) | 3000 | 480 | 460 | 340 | 37 | 850 |

| W12-40x2500 | 40(32) | 2500 | 520 | 500 | 400 | 45 | 1000 |

| W12-40x3000 | 40(32) | 3000 | 560 | 540 | 420 | 45 | 1200 |

| W12-45x3000 | 45(35) | 3000 | 600 | 560 | 460 | 55 | 1500 |

| W12-50x3000 | 50(40) | 3000 | 620 | 600 | 470 | 55 | 1700 |

| W12-60x3200 | 60(50) | 3200 | 650 | 620 | 500 | 75 | 1800 |

| W12-70x3200 | 70(55) | 3200 | 700 | 650 | 560 | 90 | 2000 |

| W12-80x3200 | 80(65) | 3200 | 800 | 750 | 640 | 90 | 2000 |

| W12-100x3200 | 100(80) | 3200 | 860 | 800 | 700 | 110 | 2000 |

| W12-120x3200 | 120(100) | 3200 | 930 | 900 | 750 | 130 | 2500 |

| W12-150x3500 | 150(120) | 3200 | 1000 | 950 | 800 | 150 | 3000 |

|  |

|  |

|  |